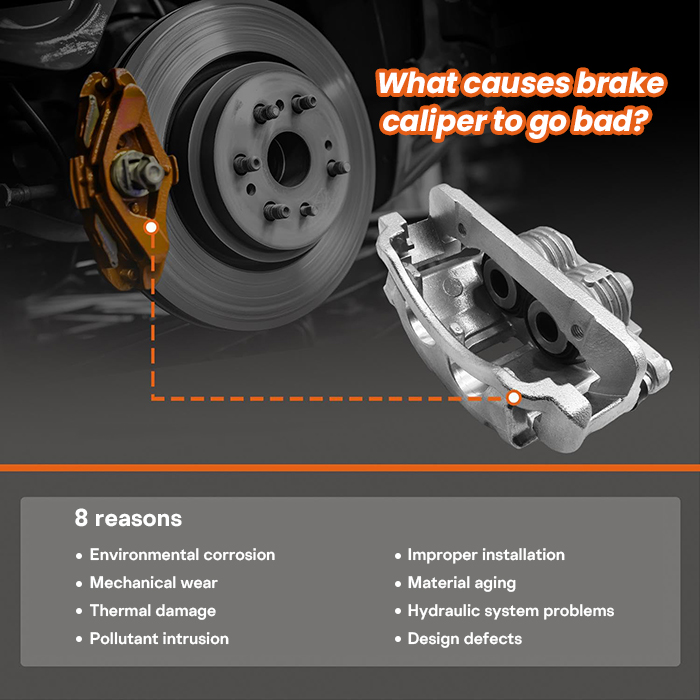

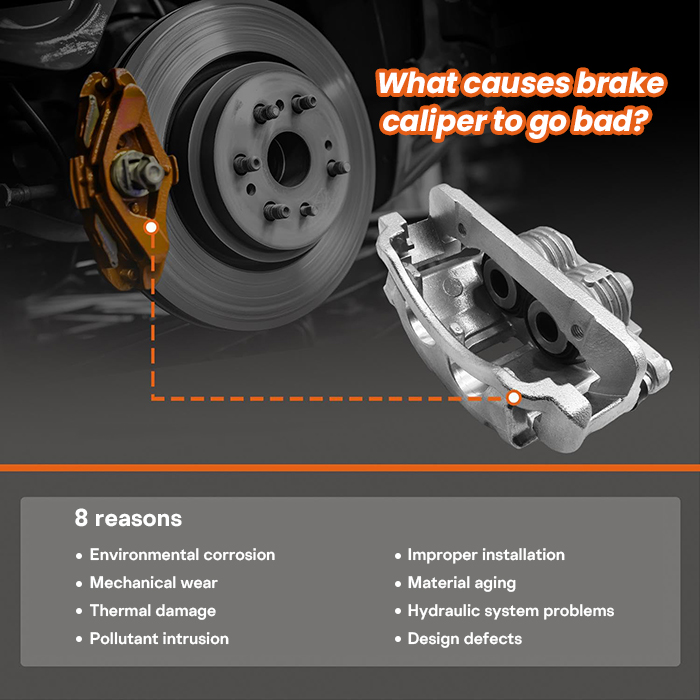

What causes brake caliper to go bad?

Introduction to the working principle of calipers

Car calipers are the core components of disc brake caliper. They use hydraulic pressure to push the piston to squeeze the brake pads and generate braking force by friction with the brake disc. A healthy caliper should have good sealing, smooth piston movement, and stable structural strength.

Main causes and mechanisms of damage

-

Environmental corrosion

Salt spray erosion: Salt in the air in coastal areas accelerates metal oxidation

De-icing agent corrosion: Chemical corrosion caused by salting roads in winter

Typical case: The rust rate of vehicle calipers in northern regions is 40% higher than that in the south

-

Mechanical wear

Wear of piston seal ring leads to hydraulic oil leakage

Abnormal wear caused by insufficient lubrication of guide pins

Direct friction of metal backing plate with caliper after excessive wear of brake pads

-

Thermal damage

Continuous downhill braking produces high temperature above 300℃

Thermal deformation causes piston jamming

High temperature causes brake fluid to vaporize and form air blockage

-

Pollutant intrusion

Sediment enters piston cavity and wears seals

Road antifreeze penetrates and corrodes metal

Water intrusion causes piston rust

-

Improper installation

Guide pin torque does not meet the standard (standard value is usually 35–45 N·m)

Wrong use of piston return tool

Brake pads are not installed in place

-

Material aging

Rubber seals age naturally in 5–7 years

Metal fatigue causes structural strength to decrease

Dust cover cracks and loses its protective function

-

Hydraulic system problems

Brake fluid contamination accelerates rubber parts degradation

Hydraulic pipeline blockage leads to abnormal pressure

Master cylinder failure causes hydraulic shock

-

Design defects

Irrational heat dissipation structure

Improper material selection

Inadequate dustproof design

Prevention and maintenance suggestions

Regular inspection

Check piston movement every 10,000 kilometers

Check whether the dust cover is damaged

Measure the remaining thickness of the brake pad

Proper maintenance

Replace brake fluid every 2 years

Use special grease to maintain guide pins

Avoid high-pressure water gun direct spraying calipers when washing the car

Driving habits

Avoid long-term continuous braking

Lightly press the brake after wading to remove water

Do not wash the car immediately after parking

Maintenance precautions

Use original disc brake calipers or high-quality aftermarket brake caliper

Strictly install according to torque requirements

Check the caliper status when replacing brake pads—this is often a good time to consider brake caliper replacement if significant wear or damage is detected.

Caliper damage is often the result of multiple factors. By understanding these reasons, car owners can take targeted preventive measures to extend the service life of the caliper and ensure driving safety. When the above warning signals appear, it is recommended to go to a professional maintenance point for inspection immediately.